2°/ Layout of supports

A second rule to be observed is to maintain a complete and permanent contact between the strip and the LIMBEROLLER® discs, both empty and loaded. The choice of belt therefore also great importance.

Failure to observe this rule results in rapid, cone-shaped wear of the outer wafers and the roll-out of service. To ensure that the conveyor belt correctly fits the LIMBEROLLER® trough shape on an existing installation, proceed as follows :

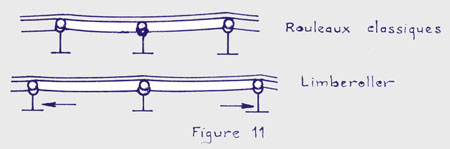

a) Increase the distance between the supports generally from 0.30 to 0.60 m compared to the practical distances with conventional metal rollers. (See paragraph below).

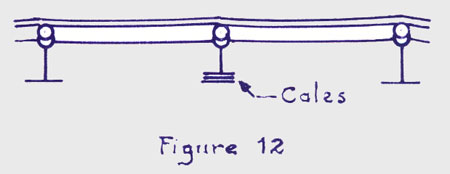

b) Raise brackets too low, using thickness shims until proper contact is obtained.

Obviously, operations a and b can be combined.

|